Blog

Gambling

Interesting Facts from History: The Formation of Online Gambling

It’s no secret that today there are a large number of online casino platforms. To play or not to play? ...

Technology

The Power of Effortless Large File Sharing in the Digital Age

Not long ago, the best way to send large files to someone was to physically send them a storage device ...

Uncategorized

How to Transform Your Cooking Space with Sleek Glass Splashbacks!

Do you love to cook and prepare delicious meals for your family? And how big are you on home renovations ...

Fashion & Style

Considerations and Challenges in Designing Plus Size Formal Dresses

Gone are the days when a 36-24-36 body stat was considered to be the norm, and any variation was an ...

Cryptocurrency

PayPal Stablecoin Could be a Game-Changer for the iGaming Industry

PayPal announced that customers could purchase, hold, and sell Bitcoin, Ethereum, Litecoin, and Bitcoin Cash directly in their PayPal account ...

Business

Want to Become a Realtor in MI? Here’s What You Must Know

Recent studies showed that the number of new homes purchased in Michigan grew by over 10% in 2023. Furthermore, experts ...

Business

Top Contactless Payment Solutions for Small Businesses: Features and Costs

In today’s world of modern habits and fast living, convenience reigns supreme. It’s completely understandable because everyone wants to get ...

Business

The Relationship Between Google Searches And Consumer Trust

The digital age has given rise to various online trends. User information and sensitive details are available all over the ...

Law

DWI vs. DUI: Understanding the Legal Distinctions – 2024 Guide

Understanding traffic laws can often feel like deciphering a dense legal tome, especially when it comes to understanding the distinctions ...

Blog

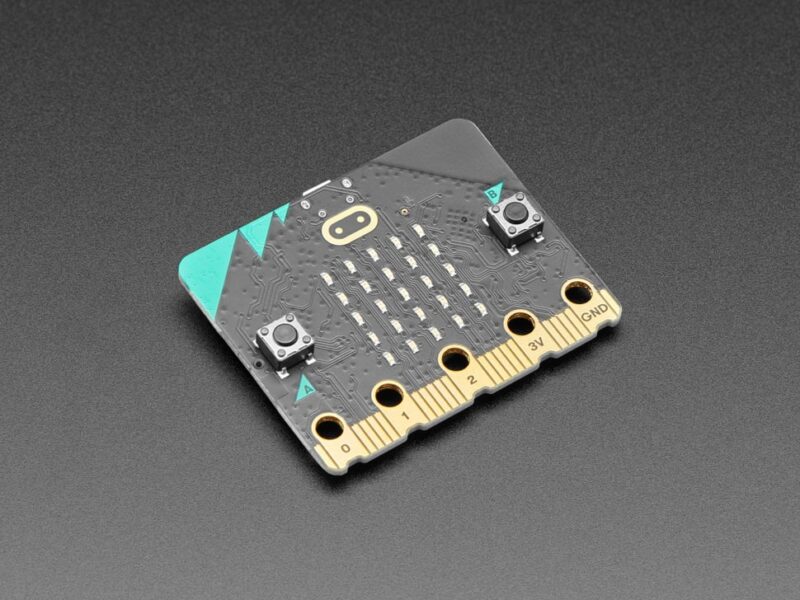

Getting Started with BBC micro:bit: A Step-by-Step Tutorial

The BBC micro:bit is a compact, powerful microcontroller designed to make learning and teaching digital skills, coding, and electronics both ...