Shot blasting is a vital process in many industries, from manufacturing to construction, used to clean, strengthen, or polish a surface. Whether you’re removing rust from metal, preparing surfaces for coatings, or giving concrete a textured finish, the right blasting material is crucial for achieving the best results. For businesses involved in shot blasting, choosing the right shot blasting material supplier is essential for efficiency, quality, and consistency.

In this post, we’ll take a closer look at shot blasting materials, what to consider when selecting a supplier, and why the right supplier matters for your project.

What Is Shot Blasting?

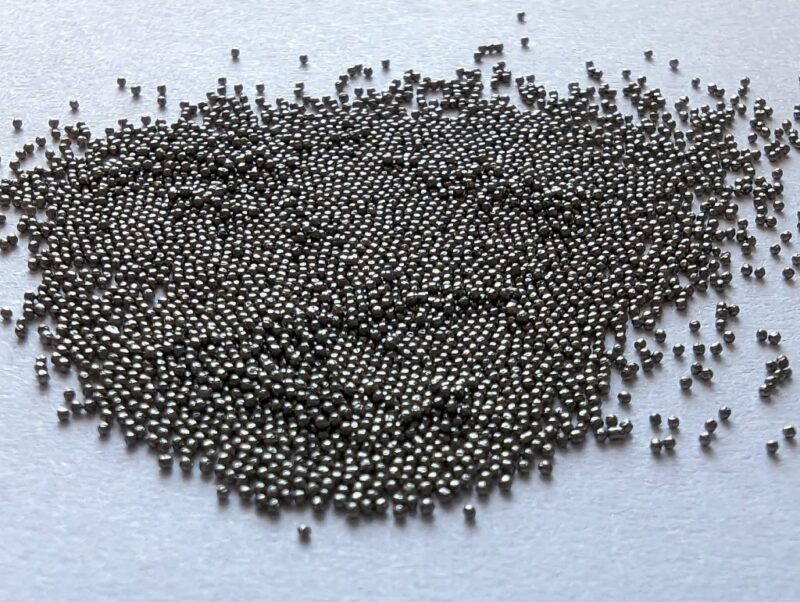

Shot blasting is a mechanical surface preparation technique where abrasive materials are propelled at high velocity toward a surface to clean or modify its finish. It’s commonly used to remove contaminants, corrosion, old coatings, or to prepare a surface for further treatment like painting or sealing.

The materials used in shot blasting vary depending on the job. The most common include steel shot, steel grit, glass beads, and aluminium oxide. Each material has different characteristics, such as hardness, shape, and size, which make them more suitable for specific applications. For instance, steel shot is ideal for cleaning and polishing metals, while glass beads are often used for delicate surface cleaning or aesthetic finishing.

In addition to surface preparation, shot blasting also improves product longevity. By removing impurities and creating a uniform surface profile, the adhesion of coatings or paints is significantly enhanced, reducing the risk of flaking, peeling, or corrosion over time.

Types of Shot Blasting Materials

There’s no one-size-fits-all solution when it comes to shot blasting materials. The right material depends on factors such as the type of surface being treated, the desired finish, and the nature of the contaminants being removed.

Steel Shot and Steel Grit

Steel shot is typically used for cleaning, peening, and polishing metal surfaces, while steel grit is harder and is ideal for cleaning rust or corrosion from steel surfaces. Steel shot also provides a more uniform finish compared to grit, making it suitable for more delicate jobs. Its round shape reduces surface damage while still effectively removing scale and contaminants.

Aluminium Oxide

Known for its durability and aggressive cutting power, aluminium oxide is widely used for surface preparation in aerospace, automotive, and foundry applications. It’s ideal for cleaning heavy rust and preparing metal surfaces for coating. One advantage of aluminium oxide is its recyclability—it can be reused multiple times before losing its cutting effectiveness.

Glass Beads

Glass beads are more delicate than steel or aluminium-based abrasives, making them suitable for cleaning without damaging the underlying surface. They are often used in industries where a smooth, non-abrasive finish is required, such as in the automotive or medical device sectors. Glass beads are also popular for achieving a satin or matte finish.

Plastic Abrasives

For more delicate surfaces that need cleaning without causing damage, plastic abrasives are ideal. They are often used in industries where precision is essential, such as electronics or aerospace. These materials are also environmentally friendly and generate less dust, which can be a benefit in cleanroom or indoor applications.

Other Materials

Suppliers may also offer specialized blasting media like walnut shells, corn cob grit, or garnet, depending on the application. These are often used for specific tasks, such as stripping paint or cleaning delicate components. Garnet, for example, is often used in waterjet cutting and dry blasting for its sharpness and minimal dust production.

Choosing the Right Shot Blasting Material Supplier

When selecting a shot blasting material supplier, there are a few key factors to consider:

Quality of Materials

The quality of the blasting media plays a major role in the effectiveness of the process. Reputable suppliers provide high-quality, consistent materials that ensure optimal performance and finish. Low-grade materials can break down quickly and result in uneven finishes or increased consumption rates.

Range of Materials

A good supplier should offer a variety of materials to meet the specific needs of different industries and applications. They should be able to advise on the best material for the job, whether you’re cleaning, polishing, or finishing a surface. Some suppliers even provide custom blends tailored to unique project requirements.

Pricing and Delivery

Cost-effectiveness is always important, but it’s also crucial to find a supplier who can provide reliable delivery times. Delays in obtaining materials can halt projects, so it’s important to choose a supplier with a strong reputation for timely deliveries. Consider suppliers who offer volume discounts, flexible shipping options, or local warehousing.

Expert Advice and Customer Support

A supplier who offers technical support and expert advice can be an invaluable resource. Whether you need guidance on choosing the right material, troubleshooting equipment issues, or learning about the latest blasting technology, customer support can help ensure your processes run smoothly. Look for suppliers who provide detailed datasheets, safety guidelines, and training when needed.

Why the Right Supplier Matters

Choosing the right shot blasting material supplier can significantly impact your project’s efficiency, cost-effectiveness, and final result. Suppliers who provide high-quality materials and excellent service will help you avoid delays, ensure better surface finishes, and reduce the likelihood of needing to redo jobs.

Whether you’re a small business or a large industrial operation, partnering with a trusted shot blasting material supplier is crucial for achieving the best possible results every time. By taking the time to research and select the right supplier, you’ll ensure your projects are completed on time, within budget, and to the highest standard. In the long run, a reliable supplier is not just a vendor—they become a strategic partner in your operational success.