Quality problems cost manufacturers more than most people realize. A well known industry survey from the American Society for Quality estimates that poor quality can drain up to 15 percent of revenue through scrap, rework, and returns.

That single number usually gets a reaction. If defects are that expensive, the obvious question becomes how factories can catch issues earlier, faster, and more consistently. That is where automated inspection enters the picture.

Instead of relying on tired eyes and manual checks, modern production lines increasingly depend on cameras, sensors, and software that never blink. Understanding how automated inspection works helps explain why it has become a backbone of modern manufacturing.

What automated inspection really means in manufacturing

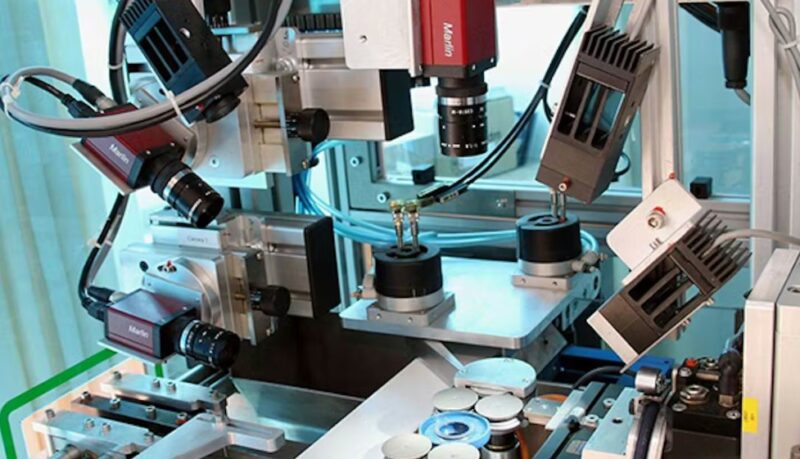

Automated inspection in manufacturing refers to the use of machines, sensors, and software to evaluate products without constant human involvement. This can include visual inspection, dimensional checks, surface analysis, and functional verification, all performed at production speed. The goal is simple but powerful: detect defects as early as possible and do it the same way every time.

In practice, automated inspection systems sit directly on the production line. Parts move past cameras or sensors, data is captured in milliseconds, and software compares each item against defined quality standards. When something falls outside tolerance, the system flags it or removes it automatically.

Key elements usually include:

- Imaging hardware such as industrial cameras and lenses

- Lighting designed to highlight relevant features

- Processing software that evaluates images or signals

- Integration with production controls for real-time response

This combination replaces subjective judgment with repeatable, measurable decisions.

Core technologies that make automated inspection possible

Behind every automated inspection setup is a mix of hardware and software working together in real time. Cameras capture visual data, sensors measure physical properties, and processors analyze everything almost instantly. Industrial cameras are especially important because they must operate reliably in harsh environments with vibration, dust, and variable lighting.

In many modern systems, manufacturers rely on high-speed interfaces that can handle large image files without lag. This is where solutions like VA Imaging’s high-performance USB3 lineup fit into the conversation. USB3 Vision cameras provide fast data transfer, stable connectivity, and flexibility for different inspection tasks, making them suitable for lines that demand both speed and accuracy.

On the software side, algorithms compare captured data to reference models. These can be rule-based systems using thresholds, or more advanced machine learning models trained on thousands of examples. The combination of robust hardware and intelligent software is what makes automated inspection reliable at scale.

Step by step flow of an automated inspection process

Understanding the flow of automated inspection helps demystify what happens on the factory floor. While setups vary, most systems follow a similar sequence from capture to decision.

First, the part enters the inspection zone, where lighting is carefully controlled. Consistent lighting is critical because shadows or glare can create false defects. Next, cameras or sensors capture images or measurements at precise moments, often synchronized with conveyors or robotic arms.

After capture, software processes the data in real time. Features like edges, holes, colors, or dimensions are extracted and compared against predefined tolerances. Finally, the system makes a decision and triggers an action.

Typical actions include:

- Approving the part and allowing it to continue

- Rejecting it via a diverter or robot

- Logging data for traceability and analysis

All of this happens in fractions of a second, without slowing production.

Types of defects automated inspection is designed to detect

Automated inspection is not limited to a single type of flaw. Systems are designed around the specific risks of each product and process. In electronics manufacturing, inspection often focuses on solder joint quality, missing components, or alignment issues. In automotive production, surface defects, dimensional accuracy, and assembly verification are common targets.

Visual inspection systems excel at detecting:

- Scratches, cracks, and surface contamination

- Color mismatches or printing errors

- Missing or misaligned components

Non-visual sensors add another layer. Laser scanners measure dimensions, while infrared sensors can detect temperature anomalies that indicate internal problems.

Did you know?

Many manufacturers discover new defect patterns only after implementing automated inspection, because machines catch subtle variations humans tend to overlook. Over time, this leads to tighter process control and fewer surprises downstream.

Where automated inspection fits into the production line

Automated inspection can be placed at different stages of manufacturing, depending on the risk and cost of defects. Some inspections happen right after a critical operation, such as machining or soldering, to catch errors immediately. Others are positioned at the end of the line as a final quality gate before shipping.

Early inspection has a clear advantage. Catching a defect right after it occurs prevents additional value from being added to a faulty part. This reduces waste and simplifies root cause analysis. End-of-line inspection, on the other hand, ensures that no defective products reach customers.

A common strategy combines both:

- In-process inspection after high-risk steps

- Final inspection for overall compliance

This layered approach balances speed, cost, and quality assurance across the entire production flow.

Comparing manual and automated inspection approaches

To understand the value of automated inspection, it helps to compare it directly with manual methods. Both have a place, but their strengths and limits are very different.

|

Aspect |

Manual inspection |

Automated inspection |

| Consistency | Varies by operator | Highly repeatable |

| Speed | Limited by human pace | Matches line speed |

| Fatigue | Affects accuracy | No fatigue |

| Data collection | Minimal | Extensive and structured |

Manual inspection can be flexible and intuitive, especially for low volumes or complex judgments. Automated inspection excels when volumes are high, and standards must be applied uniformly. Most modern factories use a hybrid approach, relying on automation for routine checks and humans for exceptions and process oversight.

The future of automated inspection in manufacturing

Automated inspection continues to evolve as computing power and artificial intelligence improve. Machine learning models are becoming better at handling variation, reducing the need for rigid rules. This makes inspection systems more adaptable to real-world conditions.

Integration is another trend. Inspection data increasingly connects with predictive maintenance, supply chain systems, and digital twins of production lines. Quality information no longer lives in isolation but informs broader operational decisions.

As labor markets tighten and quality expectations rise, automated inspection will likely become even more central to manufacturing strategy. Companies that understand how these systems work, and how to implement them thoughtfully, gain more than defect detection. They gain visibility, control, and confidence in every unit they produce.

In the end, automated inspection is not about replacing people. It is about giving teams better tools to build products right the first time, every time.