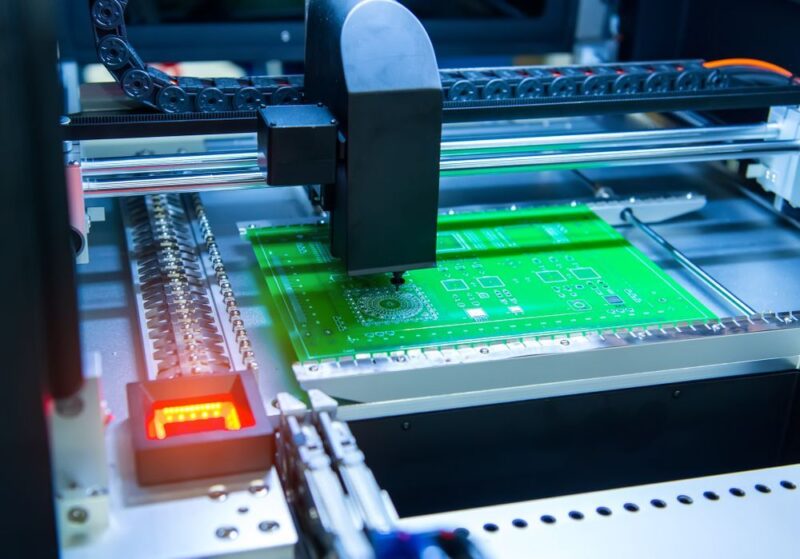

In the realm of electronics enthusiasts, the term “PCB assembly” often ignites a spark of curiosity and creativity. Imagine the satisfaction of transforming a blank circuit board into a functional masterpiece that powers your ingenious electronic creations. PCB assembly, short for Printed Circuit Board assembly, is the heart of electronics design—a process that bridges the gap between ideas and reality. In this guide, we will delve into the art of DIY PCB assembly, equipping you with the knowledge and skills to embark on your own electronic journeys.

Why PCB Assembly Matters

From the humblest of gadgets to the most sophisticated devices, PCBs are the unsung heroes that orchestrate the symphony of electronic components. They provide the canvas upon which intricate designs come to life, facilitating the flow of electricity, data, and signals. For electronics enthusiasts, mastering PCB assembly unlocks a realm of possibilities. By learning this skill, you gain the autonomy to transform your ideas into tangible devices, custom-tailored to your specifications.

Understanding PCBs

At its core, a Printed Circuit Board (PCB) is a flat board composed of insulating material with conductive pathways etched onto it. These pathways, often made of copper, form the circuit connections between various electronic components. A PCB, and companies that excel in its manufacturing such as Vinatronic, not only simplifies the assembly process but also enhances the reliability and efficiency of electronic devices.

Diverse Types and Applications

PCBs come in various forms, each optimized for specific applications. Single-layer PCBs are ideal for simple circuits, while multilayer PCBs accommodate complex designs by incorporating multiple conductive layers. Flexible PCBs bend to fit unique shapes, making them suitable for wearables and small form-factor devices. Whether you’re crafting a handheld gadget, a smart home device, or a robotic marvel, PCBs provide the foundation for innovation.

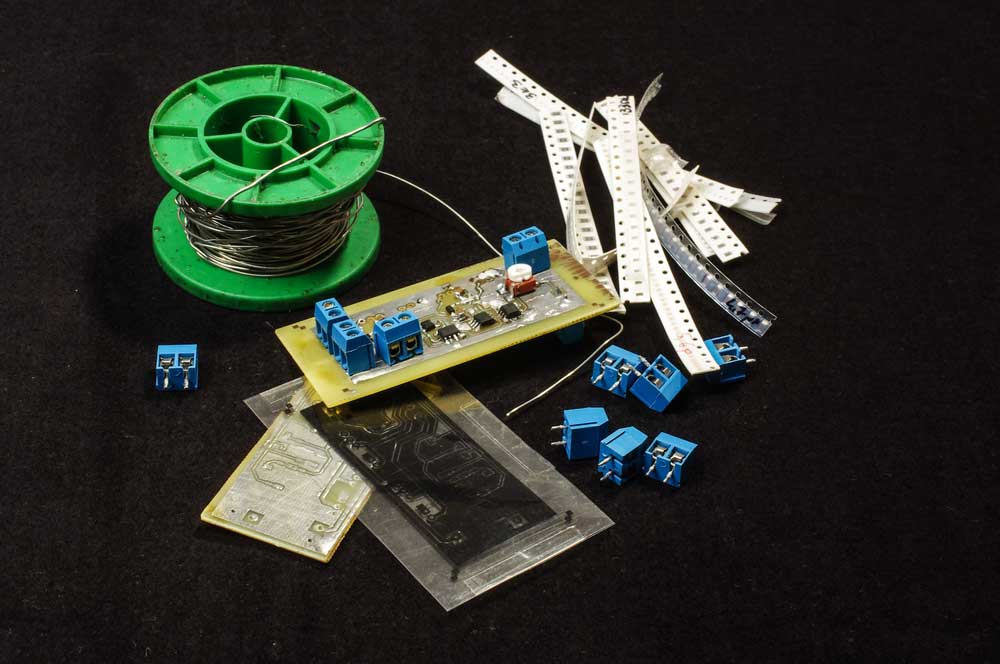

Essential Tools and Equipment

Before diving into PCB assembly, gather the necessary tools: a soldering iron, flux, solder wire, multimeter, and more. The soldering iron fuses components onto the PCB, while flux aids in solder flow and improves joint quality. A multimeter, the Swiss Army knife of electronics, measures voltage, current, and resistance, assisting in troubleshooting and quality assurance.

Safety Precautions

Working with electronics demands mindfulness of safety. Adequate ventilation prevents inhalation of harmful fumes emitted during soldering. Donning eye protection shields your vision from solder splatters. An organized workspace not only boosts efficiency but also reduces the risk of accidents. Remember, a safety-conscious approach is the cornerstone of an enjoyable and risk-free DIY electronics journey.

Soldering Techniques

Soldering serves as the crucial bridge that unites electronic components with the PCB. This intricate process involves the controlled melting of solder wire, resulting in a sturdy, conductive joint. When it comes to soldering, you have two primary options: through-hole soldering and surface mount soldering. Through-hole involves threading components through pre-drilled holes in the PCB, while surface mount involves attaching components directly to the board’s surface. However, the journey to becoming a soldering maestro goes beyond choosing a method.

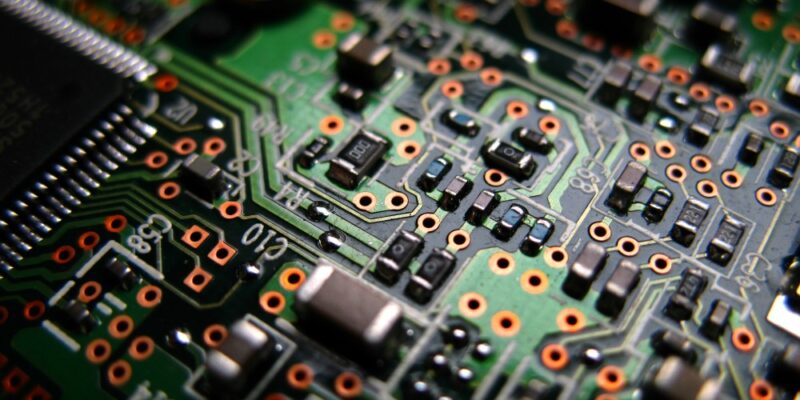

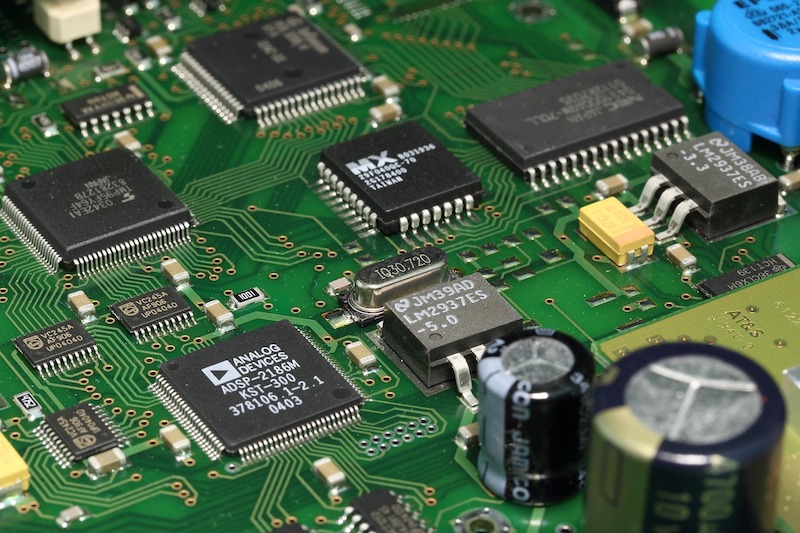

Component Identification

As you embark on your PCB assembly journey, you’re entering a realm that may seem cryptic at first glance—a circuit board laden with diverse components, each with a specific purpose. Learning to decipher this puzzle is an exhilarating challenge. Imagine being able to identify resistors, those tiny color-coded cylinders that regulate current; capacitors, which store and release energy; diodes, one-way traffic controllers for electrical current; and integrated circuits (ICs), the brains behind the operation.

Each of these components contributes a distinct note to the symphony of your electronic creation. Visual aids and concise explanations will be your guides through this labyrinth. Soon, you’ll discern the unique roles of these components, allowing you to wield your soldering iron with precision, creating connections that orchestrate your electronic vision.

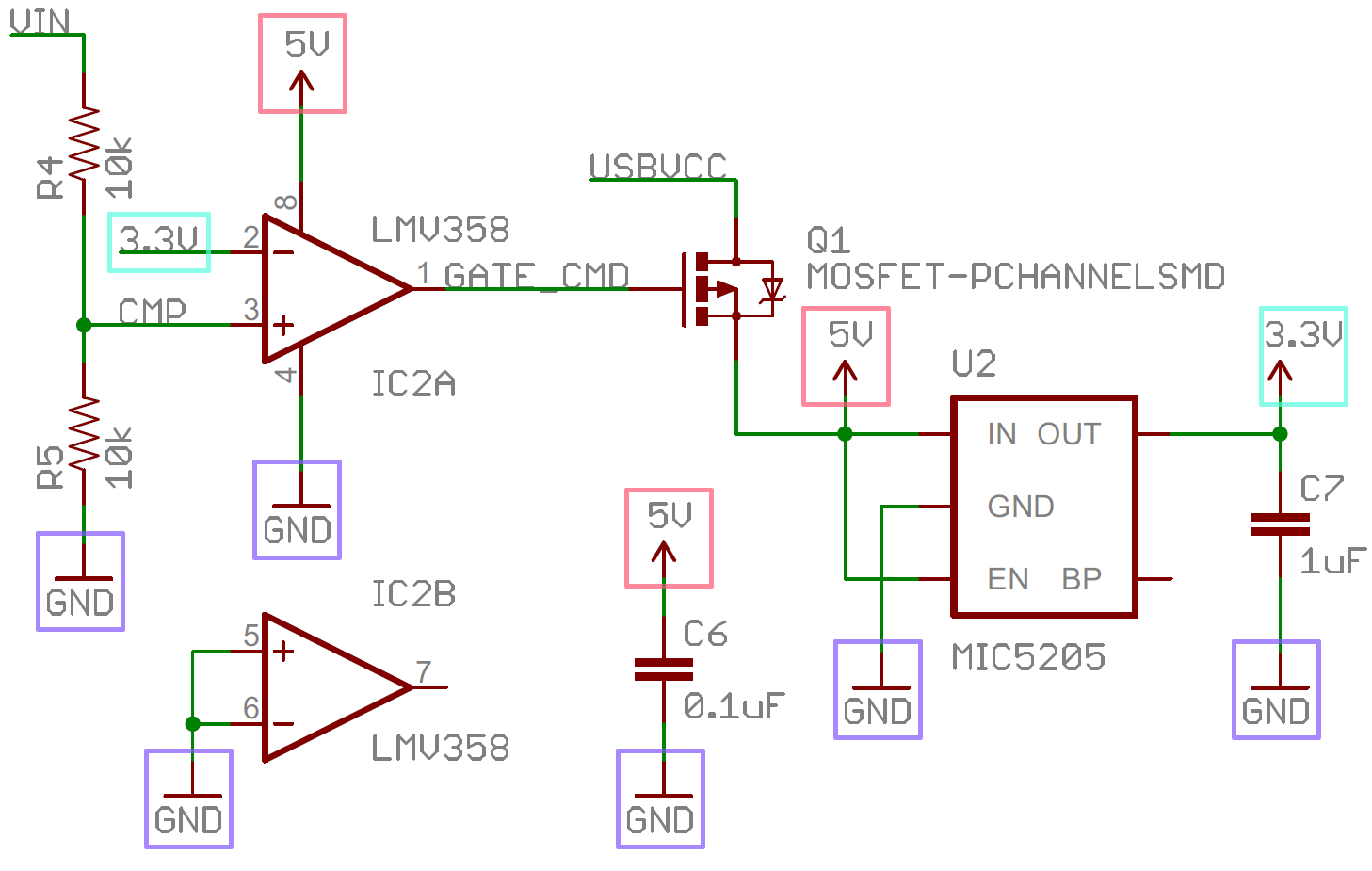

Reading Schematics

In the world of electronics, schematics are the language of design. They are the blueprints that unravel the intricacies of a circuit’s architecture. As you embark on your PCB assembly journey, mastering the skill of reading schematics is your ticket to bringing your ideas to life. These visual representations map out how components connect and communicate, much like the lines of a musical score guiding an orchestra.

Understanding symbols and conventions is the key to unlocking this visual language. Diodes, capacitors, and resistors become familiar friends, and you’ll decipher the flow of signals with ease. With this skill, you’ll bridge the gap between theory and reality, transforming abstract concepts into tangible, functional assemblies.

PCB Layout Considerations

Designing a PCB layout is a symphony of aesthetics and functionality. Imagine yourself as a conductor, arranging the placement of components like musicians on a stage. But it’s not just about aesthetics—it’s about creating an efficient, noise-free environment for your electronic symphony. Careful component placement, well-routed signal traces, and thoughtful ground plane design harmonize to ensure your creation performs optimally.

Signal traces act as the melodies, carrying electrical currents between components. To avoid distortion or interference, these traces must be thoughtfully organized. Ground planes, the bass line of your electronic composition, provide a stable reference point for signals. A well-considered layout not only minimizes noise but also enhances the overall performance of your circuit, ensuring that your creation hits all the right notes.

Troubleshooting and Testing

Even the most seasoned DIY enthusiasts encounter roadblocks. Learn how to troubleshoot common issues, such as solder bridges and faulty connections. Utilize various testing methods, like continuity checks and functional testing, to validate your creation’s integrity.

Resources for PCB Fabrication

While DIY assembly is rewarding, professional fabrication elevates your projects. Explore online resources and software tools that simplify PCB design. Discover fabrication services that transform your designs into professionally manufactured boards, achieving a polished finish.

Advanced Tips and Future Learning

As your skills mature, so can your designs. Unlock advanced techniques for intricate PCBs and delve into specialized realms like high-frequency designs and mixed-signal layouts. Fuel your passion by delving into advanced electronics courses and engaging with vibrant community forums.

Conclusion

The world of DIY electronics beckons with promise, creativity, and innovation. PCB assembly is the gateway that propels you from a curious enthusiast to a proficient creator. By embracing the art of PCB assembly, you’re not just mastering a skill; you’re embarking on a transformative journey that empowers you to shape the future of electronics, one circuit at a time. So, equip yourself with tools, knowledge, and passion, and let your electronic odyssey begin!