Clear equipment identification has become a central requirement across multiple industries in 2025. Businesses face growing expectations from regulators, auditors, and clients to ensure that machinery, tools, and components are labeled with precision. Correct labeling reduces safety hazards, improves traceability, and strengthens trust in supply chains.

One of the most reliable methods for achieving this is the use of metal nameplates that permanently display serial numbers, barcodes, operating instructions, and compliance marks. Their durability ensures information remains readable even in high-temperature, corrosive, or high-impact environments. Standards have advanced in recent years, creating a framework that guides manufacturers and service providers in labeling equipment accurately and consistently.

Why Standards for Equipment Identification Matter

Safety and Risk Reduction

Accurate identification helps prevent accidents in workplaces where heavy machinery and electrical systems are common. Workers rely on labels to know operating limits, lockout procedures, and warning signals. Inconsistent labeling can result in costly injuries or legal penalties.

Traceability in Global Supply Chains

Modern supply chains stretch across continents. Equipment identification standards allow regulators and buyers to trace every component back to its origin. This prevents counterfeiting and ensures authenticity of spare parts, which protects both the brand and the end-user.

Compliance With Regulations

Government agencies around the world mandate specific labeling practices for industries such as aerospace, automotive, medical devices, and food processing. Failure to comply can result in product recalls, fines, or suspension of licenses. Adhering to standards ensures smooth audits and uninterrupted market access.

These are the Core Standards

-

ISO 9001 and Quality Management

ISO 9001 sets guidelines for quality management systems. Equipment identification plays a direct role in ensuring quality processes remain consistent. Clear labeling allows inspectors and managers to verify calibration dates, maintenance records, and responsible personnel.

-

ISO 13485 for Medical Devices

Medical equipment requires precise labeling due to the life-critical role it plays. ISO 13485 enforces strict rules for identification, storage, and traceability of devices used in healthcare environments. Labels must resist cleaning agents, sterilization, and constant handling.

-

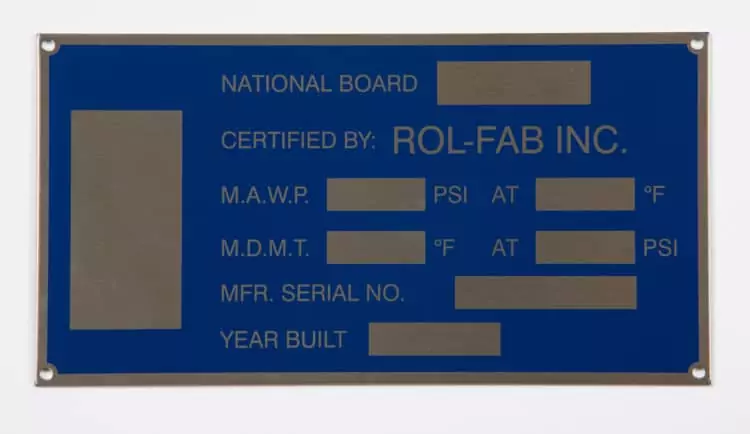

ANSI/ASME Standards

In mechanical and structural industries, ANSI and ASME standards outline requirements for safety tags, pressure vessel plates, and load-bearing equipment. These standards ensure that critical data such as working pressure, serial numbers, and load limits remain visible under demanding conditions.

-

OSHA Requirements

The Occupational Safety and Health Administration in the United States enforces labeling for hazardous machinery and equipment. OSHA guidelines dictate the size, color, and placement of safety labels to ensure workers can quickly identify potential hazards.

-

UL and CE Markings

Underwriters Laboratories (UL) and the European Conformity (CE) marks continue to hold authority in 2025. Equipment bearing these certifications demonstrates compliance with electrical, mechanical, and environmental standards required for entry into regional markets.

Materials and Methods Used in Identification

Metal Nameplates

Stainless steel, aluminum, and brass nameplates provide unmatched resistance against corrosion, abrasion, and weathering. Their longevity makes them suitable for outdoor equipment, industrial plants, and marine environments.

Plastic and Polymer Labels

Polycarbonate and polyester labels offer cost-effective solutions for indoor equipment. They can include adhesive backing, clear overlays, and color coding for enhanced visibility.

RFID and Smart Tags

Radio-frequency identification technology is increasingly common in logistics and industrial tracking. Smart tags allow automated systems to scan equipment without direct line-of-sight, improving inventory control and maintenance scheduling.

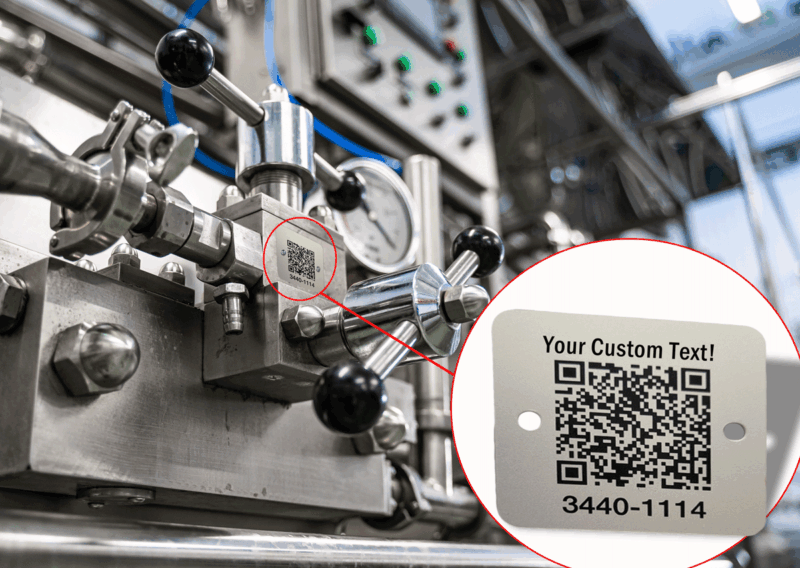

Laser Engraving and Etching

Permanent engraving ensures critical information cannot be removed or altered. Industries such as defense, aerospace, and oil and gas prefer laser-etched labels due to tamper resistance and clarity.

Compliance Challenges in 2025

Global Regulatory Complexity

Businesses that operate internationally must meet multiple sets of labeling standards. A product exported from the United States to Europe or Asia may need to comply with UL, CE, and additional country-specific rules simultaneously.

Counterfeit and Fraud Risks

Unauthorized labels can create false impressions of compliance. Manufacturers must secure supply chains and implement anti-counterfeit measures such as holographic seals, unique QR codes, and blockchain-based tracking systems.

Technological Integration

The rise of Industry 4.0 requires labels to integrate with digital systems. Data from labels must connect to enterprise software, maintenance schedules, and safety audits. Failing to align physical labeling with digital tracking introduces compliance gaps.

Best Practices for Businesses in 2025

Align With Recognized Standards

Adopt ISO, ANSI, OSHA, and sector-specific requirements as the baseline for equipment identification. Conduct internal audits regularly to verify compliance.

Choose Durable Materials

Select labeling materials based on the environment in which the equipment operates. For example, metal nameplates work best in outdoor oil fields, while polymer labels may suit office electronics.

Train Employees

Employees must understand the meaning of each label and the legal significance of altering or removing identification. Regular training reinforces awareness and accountability.

Integrate Digital Systems

Pair physical labels with digital records in enterprise resource planning (ERP) or computerized maintenance management systems (CMMS). This dual approach ensures every asset is traceable in real-time.

Monitor Global Developments

Keep up with evolving global standards. Regulatory updates in the European Union, North America, or Asia can affect export readiness. Being proactive avoids costly retrofits.

Future Outlook for Equipment Identification

In 2025 and beyond, labeling will move closer to complete digital integration. QR codes, NFC chips, and blockchain databases will allow instant verification of authenticity and compliance. Artificial intelligence will analyze identification data to predict maintenance needs and detect irregularities.

Sustainability will also influence material selection. Manufacturers will seek eco-friendly substrates for labels that maintain durability but reduce environmental impact. Recyclable metals and biodegradable polymers are entering the market as industries balance performance with responsibility.

Conclusion

Industry standards for equipment identification in 2025 are designed to create safer workplaces, transparent supply chains, and legally compliant operations. By following ISO, ANSI, OSHA, and regional guidelines, businesses protect employees, prevent costly penalties, and build stronger customer trust.

Durable materials such as metal nameplates, advanced methods like laser engraving, and emerging technologies such as RFID and QR codes form the backbone of effective labeling. Companies that integrate these practices with digital compliance systems will remain competitive in the years ahead.